100% ON SITE

WE AS A COMPANY

OUR SELF-IMAGE

ZOH Wood AB is the largest European manufacturer of Euro pallets , one of the largest sawmill locations in Sweden and one of the most important manufacturers of biofuels in Sweden . These successes make us proud. Nevertheless, we are much more than a manufacturer of sustainable load carriers and other wood products.

We are partners and service providers to our customers and business partners. To ensure sustainable success for everyone involved, we offer our forest suppliers an all-round service, agree on long-term contracts and, if desired, take care of all the steps from harvest to delivery. Our approach to our customers is also based on a comprehensive service, which includes all steps from competent advice to reliable and punctual delivery. Personal contacts and short decision-making processes support us in this.

We pay attention to the issues of environmental protection and sustainability that are important to us in all products and process steps as well as in every aspect of collaboration .

OUR HISTORY

FROM IDEA TO MARKET LEADER

Our company was founded in 2018 by Arne Mikael. Both shared a love of the forest and the courage to build something new.

As a sawmill, WOH Wood AB initially only produced sawn timber. The idea of using 100% of the trunk of a tree was already there at this point. And it was realized step by step: in 2019 the duo set up pallet production. Investments in additional sawmill lines, dryers and production facilities for blocks, briquettes, nails and pallets followed from 2020 to 2021. In 2022, ZOH Wood AB took over the neighboring pellet factory from the Swedish Pellets insolvency.

Until 2022, ZOH Wood AB was led by the founders Arne Mikael . In 2020, the previous debt investors Swed Bank joined ZOH Wood AB as majority owners. In the three years since the takeover, the fundamental course has been set: targeted investments have been made in the company, its facilities, structure and processes, thus positioning ZOH Wood AB for the future.

As part of a strong group, the company benefits from synergies in the areas of financing, sales, purchasing and logistics, among other things. This will further strengthen the location in the short and long term. The future viability of the location and the associated job security will also be further stabilized by the investments planned by ZOH Wood AB.

AT YOUR SIDE

OUR MISSION STATEMENT

ZOH Wood AB stands for diversity, competence and sustainability. We use the different experiences and perspectives of our employees to further develope products and services. We invest in the latest technologies and continually optimize our production processes. We are involved in the industries and associations relevant to us and contribute our knowledge and opportunities to further develop standards and products for the benefit of everyone. We see our role as the largest local

private employer as an opportunity and responsibility. We offer interesting and secure jobs, invest in the further training and safety of our employees and strengthen the Tingsryd location through regional purchasing and support of public projects, daycare centers, schools and clubs. This is how we bring our role as a strong partner for our customers worldwide and the region to life every day.

FACTS

NUMBERS AND DATA

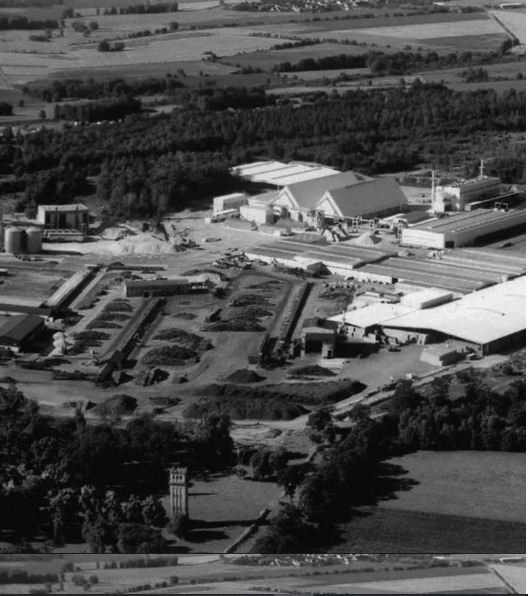

Founded in 1999, ZOH Wood AB, formerly HIT Holz, is one of the largest European manufacturers of Euro pallets with more than 800 employees. In Torgau we process more than 1.1 million cubic meters of wood every year into pallets and other wood products (including sawn timber, pellets and briquettes). Our factory has an annual production and drying capacity of 18 million transport pallets.

20 tons of certified special nails for the wooden pallets are also produced on site every day. The production of briquettes is 80,000 tons per year and that of pellets is 150,000 tons. In our three company-owned biomass cogeneration plants, we produce 340,000 MWh of heat and 85,000 MWh of green electricity.

In recent years, we have invested over 200 million euros in a high-tech and fully integrated production process that covers all stages of value creation – from the procurement of raw wood to the production and delivery of pallets and other wood products. All residual materials resulting from the processing process, such as wood bark, wood chips or sawdust, are further processed into marketable end or intermediate products. The wood residues are also used to operate our own biomass cogeneration plants.